To achieve our target of being net zero by 2025 for Scope 1 and Scope 2 emissions, and net zero by 2030 for Scope 3 emissions, we are implementing innovations to:

- Reduce our CO2 emissions from our worksites (electric/biomass-fuelled machinery, renewable energies), projects (new construction methods, low-carbon concrete, supply and traceability of low-carbon steels) and commercial offers (new uses, new markets with high environmental value)

- Protect and restore biodiversity and ecosystems

- Enhance the integration of secondary raw materials (recycling) or materials from re-use and re-purposing

- Minimise waste and maximise recovery associated with our activities

- Reduce pollution risks (noise, air, soil, water, etc.)

UBY: Sustain your constructions

To prevent noise and dust on site, UBY, an in-house technology start-up, was established by Bouygues Construction in 2019.

UBY technology utilises ‘smart’ (AI enhanced) and standard sensors, combined with specialist software and algorithms, to measure noise, air quality, vibration, energy consumption, highway impacts & water quality.

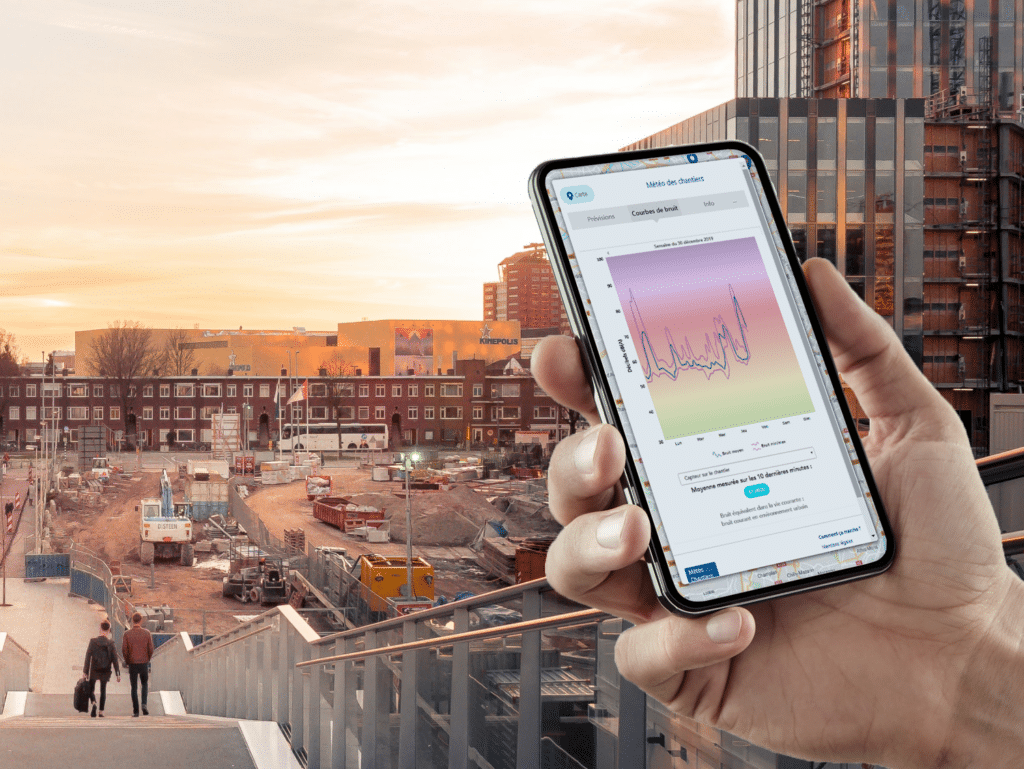

Placed at the northern boundary in one of our construction sites, where most issues could arise between structural works and large density of neighbours, this system allows our site team to establish the location of noise and dust (on site or off site), identify it, and capture an image.

Our team is then alerted to the problem before it becomes a potential nuisance or a hazard.

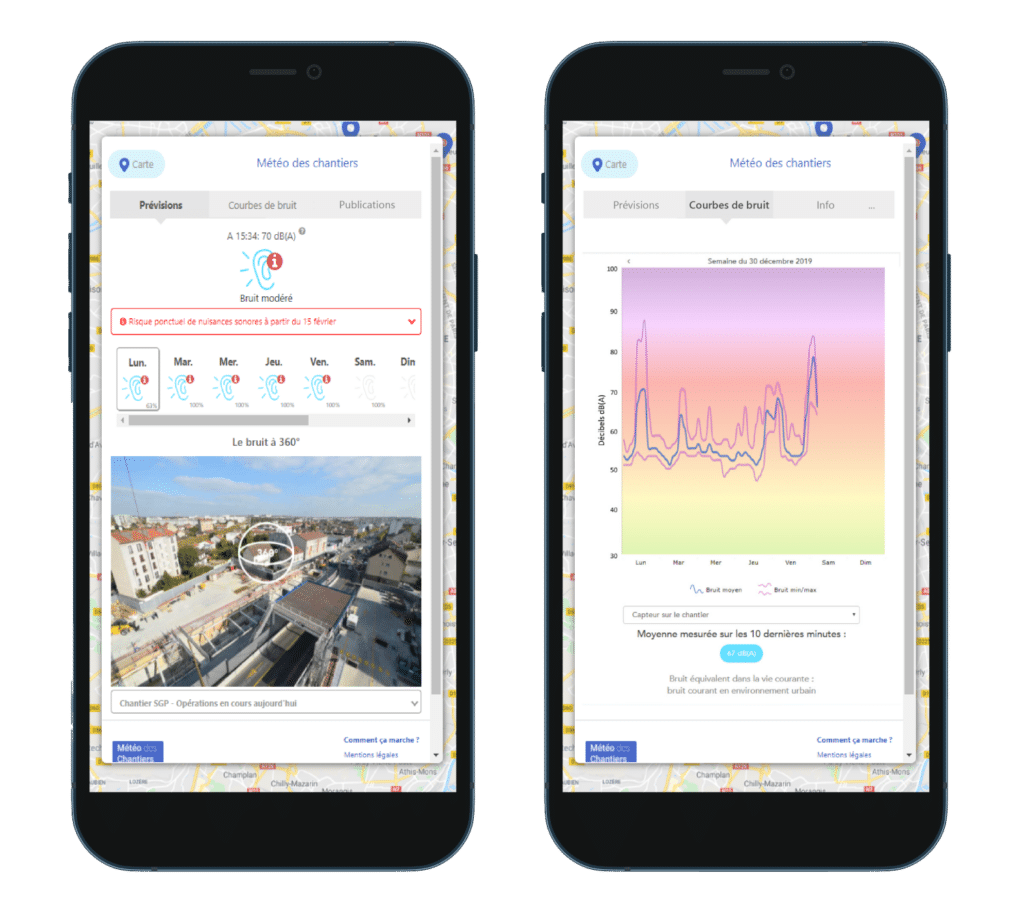

The UBY community engagement app allows our project team to report instantly on disruptive activities, provide forecasts of upcoming works, and general project information.

Furthermore, it enables the local community to submit questions to the project team and raise complaints of nuisances, should they occur.

This information is connected to the site sensors in real-time thereby enabling efficient and robust assessment of an incident or report.

Cement-free concrete

Bouygues UK trialled an innovative cement-free (Cemfree™) concrete for the mock-up construction of two walls and a ground bearing slab at our now completed Gascoigne Estate development in Barking to explore whether this environmentally friendly product provides a credible alternative to traditional concrete.

This ‘magic’ mix recipe produces a concrete without Ordinary Portland Cement (currently used worldwide), and the activator binds replacement concrete with water to ensure its strength and binding capabilities.

In the spirit of innovation and sustainable construction, Bouygues UK seized the opportunity to carry out a full-scale on-site evaluation of the product on the Gascoigne Estate project.

The wall mock-up mirrored the site conditions of the construction of a continental frame with a reinforced concrete wall, and the slab mock-up was a traditionally reinforced ground bearing slab.

The results obtained proved more than promising as the wall shutters were struck the following morning as with traditional concrete. The workability of fresh concrete satisfied the operatives, especially the quality of the finish on the slabs.

This new product is currently being tested across other construction sites to explore its potential, in line with our commitment to sustainability and low-carbon and green construction.

Automating delivery and waste management

Managing delivery information, supplier invoices, and waste transfer information on construction sites has historically been on paper requiring time-intensive processes, leading to frequent delays and administrative mistakes.

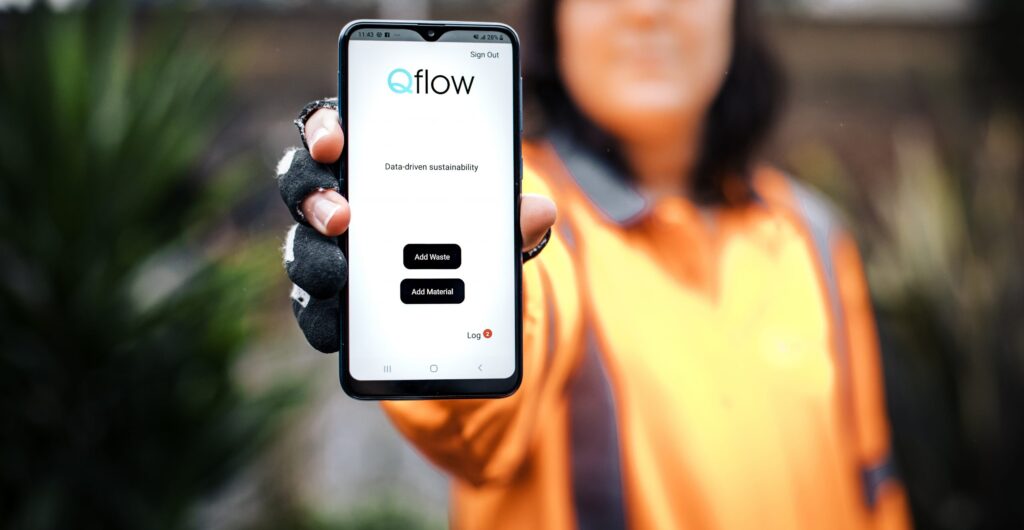

To address this challenge, Bouygues UK has joined forces with QFlow, leveraging Optical Character Recognition (OCR) technology to digitalise and organise this data within a user-friendly web portal.

This ground-breaking solution has yielded substantial time savings, boasting an impressive 95% automation rate, ensuring that all payment deadlines are now met. Furthermore, waste transfer tickets are fully compliant with UK regulatory standards, ensuring legal adherence.

The positive feedback from key stakeholders such as our logistics managers and our financial controllers underscores the efficiency and effectiveness of this innovative solution.

QFlow is currently in use across multiple Bouygues UK sites, revolutionising the way construction site data is managed.

Innovation