London

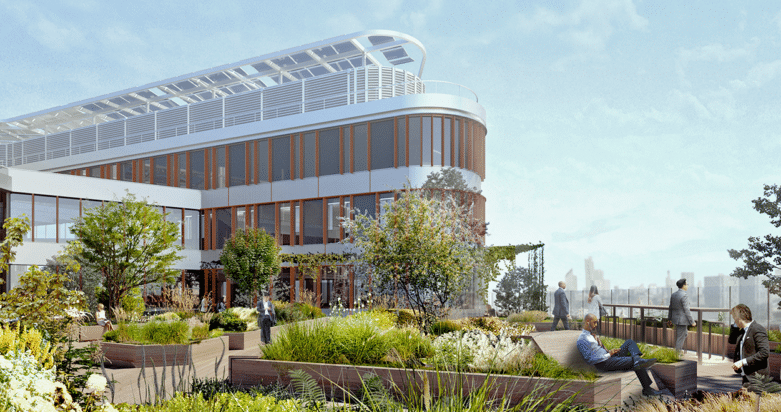

As one of the first in the UK, the Proton Beam Therapy Centre will offer world-leading new radiotherapy to patients, targeting tumours more precisely, enabling the Trust to deliver ground-breaking treatment and strengthen its position as a leading national and international cancer centre.

The project comprises the design and construction of a 34,600m2 hospital building to house a world class cancer centre of excellence adjacent to the University College of London Hospital (UCLH) in Central London. The scheme integrates a range of specialist services to provide inpatient care linked to a Proton Beam Therapy unit (PBT) housed in a 25 metre deep basement. It also incorporates a new day surgery unit to replace the current facilities housed in the UCLH tower.

Above ground there is a modern, purpose-built inpatient facility built over seven storeys making the building height equivalent to that of London’s Tower Bridge. This element of the building includes beds for specialist cancer care, comprising:

- 82 single NHS beds and 30 isolation rooms

- 52 private single bedrooms

- 10 bed ICU/HDU

- 20 bed ward (23 hours operation)

These facilities are complemented by a state-of-the-art Short Stay Surgical Centre with eight operating theatres. On site imaging facilities and appropriate critical care support functions will enable UCLH to further develop its leading role in providing specialist services in the UK.

The project was procured using a Two-Stage D&B Tender under NEC3 Option A form of contract.

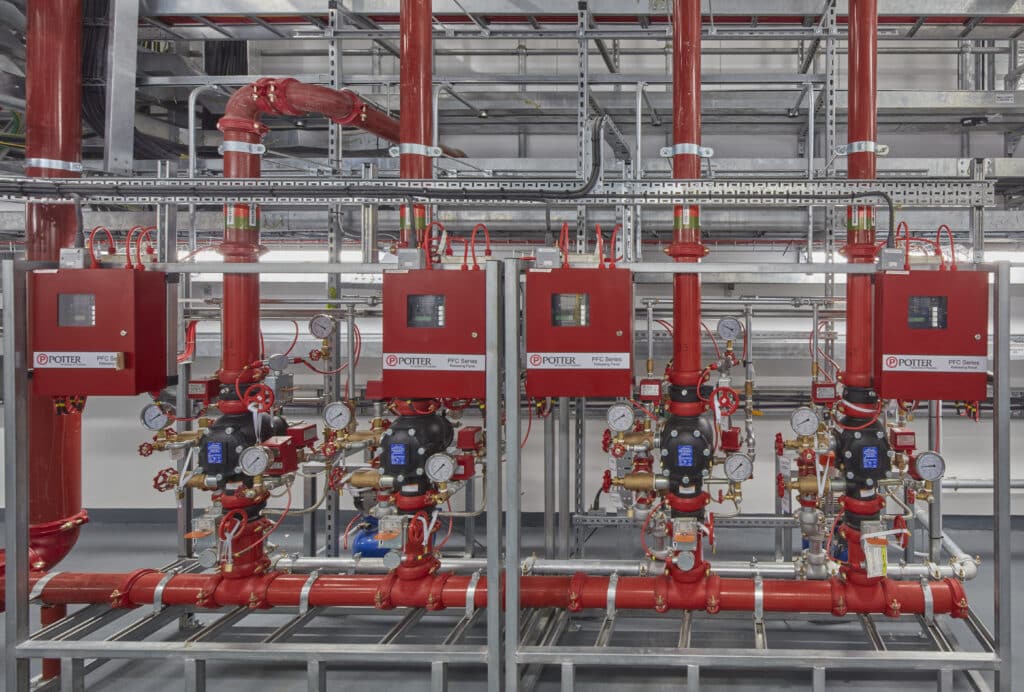

We took possession of the site with the Vacuum Insulated Evaporator (VIE) live, connected to two UCLH hospitals and requiring continuance access for maintenance, servicing and re-filled every two weeks.

Prior to any demolition and excavation works, the VIE tanks were required to be relocated within the site and upgraded to cater for the existing hospital oxygen requirements in addition to the new hospital. Access through the construction site for the lifetime of the construction was required to facilitate the bi-weekly filling and general maintenance requirements.

The existing hospital campus is made of a number of buildings in central London, the infrastructure for these buildings are connected through a series of underground tunnels that distribute services such as power, IT backbone and oxygen together with FM stores and limited patient movements. Service access from the buildings to the tunnel is below public roads and pavements. The new facilities are connected to the network by the construction of a new below ground tunnel.

The key risks related to these enabling works were identified from the early preconstruction engagements and lies with the complex interface of existing UCLH facilities that had to be dealt with and coordinated efficiently without interruption of the campus operations.

The procurement of the tanks was with UCLH Trust however Bouygues UK were tasked with the works coordination and all interim measures required for the successful relocation of these tanks.

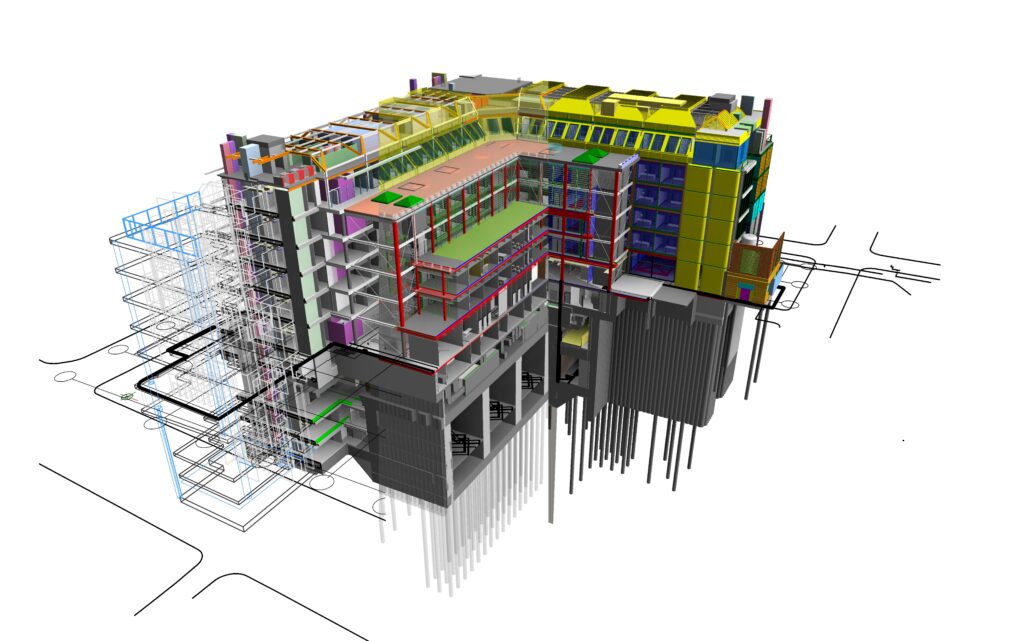

In advance of any works starting on site, the main mitigation for such intersect scope was to de-risk the process by building a virtual representation of the site existing services and environment so to visually represent potential coordination issues and resolve them with the trust teams well in advance.

Our in-house methods team were instrumental in this aspect by using a 4D BIM modelling allowing a detailed analysis of the works sequence and agreeing with the end users and project team the most efficient works executions with minimum inconvenience to the uninterrupted activities of the wider campus.

Our Approach

Our project team lead the process that required:

- Liaison with British Oxygen Company to determine the enclosure requirements for the tanks to operate safely;

- Permits for traversing the pavement and road to access the pipe system in the tunnel which was in the middle of the road – this included several licenses and determining what services had to be traversed (including fibre optic cables);

- Stage by stage diagrams depicting exactly the requirements for that stage – this including additional valves being installed in the existing pipework for future phases;

- Organising Facilities Management team and service provider to programme and define scopes;

- Presenting the detailed phasing strategy with mitigation measures to UCLH Medical Gas Committee and achieving sign off on the proposals;

- Agreeing temporary fill measures for the VIEs and developing safety protocols for staff and the public – a temporary fill point was adopted during the construction allowing safety measures to be in place during filling;

- As a mitigation measure for connecting to the existing system, a mobile VIE vehicle was agreed to be available for pre-identified areas of high acuity (maternity/NICU, A&E, operating theatres etc.) which were supplied with temporary oxygen tanks;

- Revised exhaust system to separate it from the main building construction process.

The works were executed through continuous close coordination with the existing hospitals operations and enabled uninterrupted access for filling and maintenance as required.

Key Risks

Mitigating the impact of constructing in a live environment:

We liaised regularly with UCLH to coordinate our works with campus operations. This included discussion and agreement of detailed method statements for all site works.

We met the client team weekly to discuss the short and medium term activities of all parties, with options being tabled for consideration and agreement.

Similarly, we consulted with the ambulance service and London Fire Brigade in advance of any works that might impact on emergency routes in order to identify and agree alternatives.

We were acutely aware of the sensitive nature of our operations, and their potential impact, not only on the business of the hospital itself, but also on those of neighbouring tenants and commercial premises. We therefore installed a series of sophisticated vibration and noise sensors on adjacent properties that alerted us if we were close to breaching pre-determined levels of noise or vibration.

The system was developed to identify different alarm levels depending on time of day and week. For example, we agreed in advance a reduction in the acceptable noise alarm limit at lunch times for nearby bars and restaurants.

On this project we employed the Trust’s existing multi-disciplinary design team from RIBA Stage 4 onwards. This facilitated the transfer of knowledge, building on a successful relationship and enabling us to fully understand the Employer’s requirements. We reinforced this with active stakeholder management ensuring that the Trust’s original vision, objectives, vision and clinical aspirations were met.

Through open dialogue, our approach, combines our technical know-how, capability to deliver complex projects and access to specialist expertise across the Bouygues Group, as is a fundamental driver, ensuring the smooth progression from design through construction to commissioning and helping us to achieve mutual success in project delivery.

Using UCLH as a case of best practice; we have delivered stringent Economic Deliverables as agreed with London Borough of Camden. The deliverables centred on Training, Employment, Education Interface, Upskilling, Sustainable Employment and the Provision of CCS Cards and Industry Tickets. Our CCS Score on UCLH is an excellent 45/50. Social Value is at the forefront of our minds on all our construction projects. At UCLH, we have brought social value initiatives to the table such as Minecraft and Future Cities Challenge. The challenge is an in-house competition backed by CITB which Bouygues UK devised to introduce the World of Construction to future generations using the world-famous game Minecraft. This was first introduced in 2017 as a pilot, 3 years on we have run Regional and National Finals that have proved hugely popular. This demonstrates the expanse of initiatives we deliver in line with Social Value and Community Interface.

one of the largest Basements in London

The construction of the basement was especially complex and the 83,000m3 excavation is one of the largest in London. During preconstruction, we worked with Bouygues TP our in-house civil engineering specialists to establish a workable construction methodology.

Specific dust and noise control measures were taken during demolition of the remaining part of the Rosenheim building and the removal of underground obstructions. We completed basement construction in phases. We had to support the road, to do this we installed a king post wall along the Grafton Way elevation followed by the diaphragm wall (D-wall) and capping beam to the basement perimeter. Support struts were installed at each of the four phases of excavation.

Plunged columns were installed to support a temporary steel platform from which the bulk of the excavation work was carried out. This minimised both the impact on local traffic and limited road closures.

We established displacement and movement monitoring measures on all party walls. We checked these continuously throughout the construction phases to identify and mitigate any impact of our works well in advance.

We worked closely with the Trust’s selected supplier over the installation of highly sensitive Proton Beam Therapy equipment, weighing around 60 tonnes, within the basement. We developed a solution that involved propping structural slabs to counteract the forces of the mobile cranage required to lift and lower the equipment into position 25 metres below ground.

For us it has been an incredible reinforcement of our expertise in delivering this type of project. And having built this one, we can share our expertise with our colleagues worldwide.

Gerald Farque, Managing Director, Bouygues UK

Managing the Logistical impact

At the peak of construction there were up to 160 vehicles movements to and from site each day. Set-down space was at a premium, with the site cabins being installed on a high gantry along Huntley Street.

The key to the successful delivery of the project was for our in-house methods team to de-risk the construction process before commencement. Again using our ‘Build before Build’ philosophy we built a virtual representation of the site environment. This allowed us to visualise the process in advance, and to identify and resolve issues before they arose.

By using 4D BIM we were able to analyse the construction sequence in detail, and test alternative approaches, in order to identify the most efficient construction methodology and logistics solution.

The level of detail contained in the BIM model allowed us to fabricate certain building components off site. UCLH will also use the model post completion to support the management and operation of the facility.

Working Together

On this project we employed the Trust’s existing multi-disciplinary design team from RIBA Stage 4 onwards. This facilitated the transfer of knowledge, building on a successful relationship and enabling us to fully understand the Employer’s requirements. To supplement our knowledge, we brought in Proton Beam Therapy experience through our existing network from the USA who had completed several similar schemes. We reinforced this with active stakeholder management ensuring that the Trust’s original vision, objectives, vision and clinical aspirations were met.

This approach, combined with our technical know-how, capability to deliver complex projects and access to specialist expertise across the Bouygues Group, will remain a fundamental driver, ensuring the smooth progression from design through construction to commissioning and helping us to achieve mutual success in project delivery.

This is exactly the kind of project we relish. The complexity of undertaking London’s biggest excavation within a tight site at the heart of central London enables us to add value through our technical knowledge and the infrastructure expertise of our colleagues within Bouygues Travaux Publics. This is no ordinary project: as well as being an innovative and complex build, the finished development will have the potential to improve and even save the lives of those suffering with blood disorders and complex cancers.

Fabienne Viala, Chair of Bouygues UK