We are committed to creating and building the education of the future to inspire our next generation.

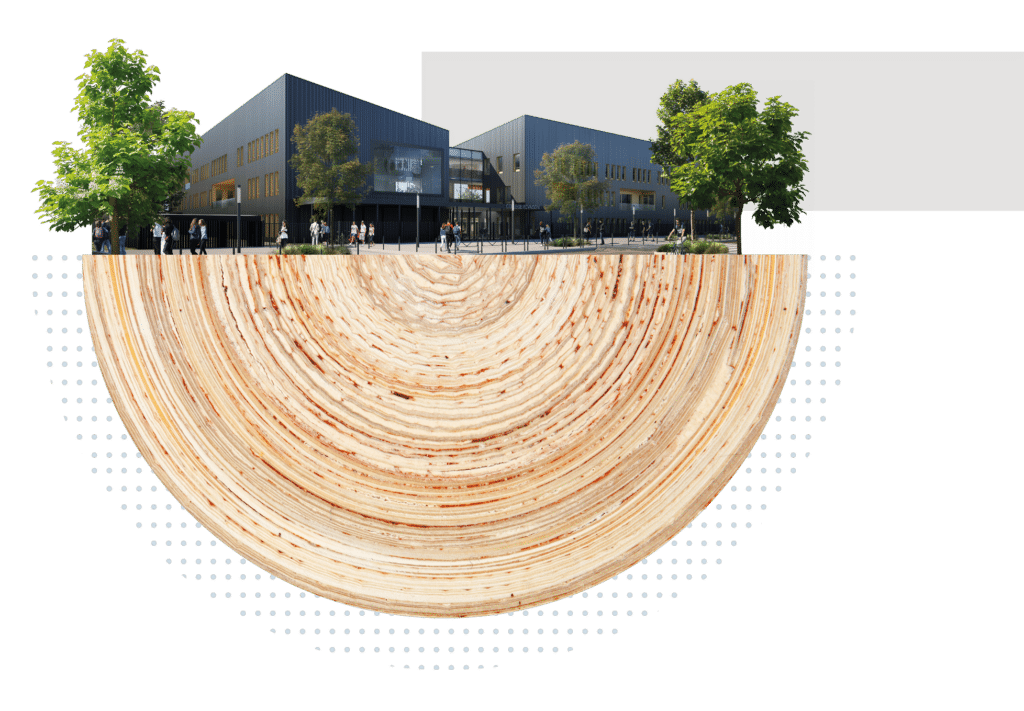

Bouygues Construction’s WeWood initiative, which aims to accelerate the use of timber within the buildings we deliver across all our sectors, is one that is harnessed across the group to achieve a more energy-efficient and environmentally friendly learning environment.

Through joining forces with other key players in the timber sector, we have been able to forge lasting partnerships and devise innovative construction methods. Such solutions have then been implemented on projects delivered by Bouygues Construction’s subsidiaries, including Bouygues UK’s own schemes.

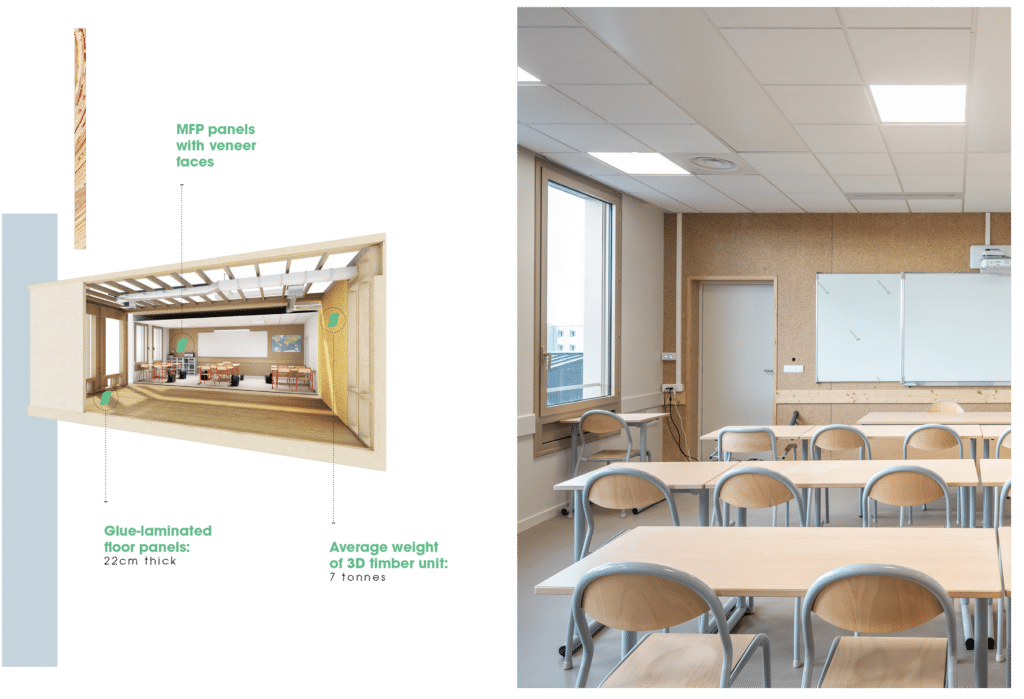

In a project partnership between Bouygues Bâtiment France, WeWood and the manufacturer Technologies & Habitats (T&H), a timber solution has been designed where wooden classroom modules are prefabricated and pre-equipped in a factory off-site to then be installed on our education schemes under construction. What sets this solution apart is its comprehensive approach. It goes beyond just prefabricating the classroom’s physical structure and envelope. Instead, it has been designed as a versatile space, providing a product that leaves the factory in as complete a state as possible. This innovative design incorporates a wide range of additional services into its structure which can then seamlessly integrate into the broader infrastructure of the scheme.

Why focus on classrooms?

With standard needs and similar compositions from one project to another, classrooms, which generally represent about 50% of a secondary school building’s makeup, are ideally suited to the design of a modular construction product, as well as industrial production.

Therefore, we closely examined the requirements of several secondary schools and colleges to identify the specifications of a typical classroom. We made sure the criteria for technical facilities, interior finishes, acoustics, fire safety and ceiling height were all considered so we could adapt to even the most demanding constraints.

This led us to concentrate on five areas:

- Floorspace management and architectural aspects of façades;

- Sizing of structural elements;

- Integration of technical systems, feasibility and interfaces with the technical trades conducted on site for the rest of the building;

- Incorporation of architectural building trades, feasibility and service limitations;

- Implementation methods concerning supply, quality control, temporary watertightness, lifting, etc.

Our goal was to provide our colleagues, clients and partners with a foundational proposal that would align with the predetermined schedule requirements outlined in the design guide sent to project coordinators, keeping sustainable construction, quality and efficiency at the heart of the programme of works.

The guide produced as a result of our extensive research specifies the technical criteria dictated by the construction method whilst remaining flexible to allow stakeholders to accommodate the unique features of each project from facade openings, orientation, ALJ (Architectural Lighting Junction), to thermal requirements, surface areas, and more.

College Revaison

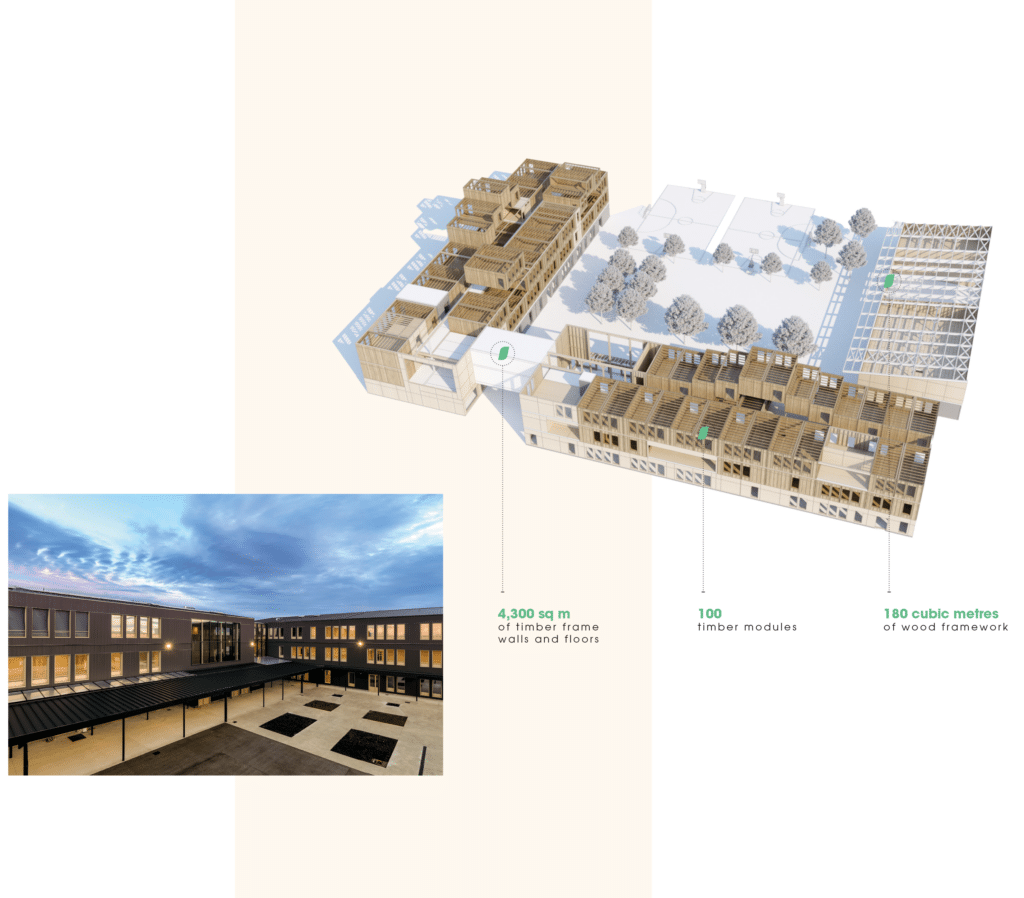

Located in Saint – Priest near Lyon in south-eastern France, the Collège Revaison is the second secondary-level school in France to be built off-site.

With an area of 7,650 m2, the Collège Revaison consists of 3 buildings intended to accommodate 750 students in 32 classrooms. In total, 90% of the establishment was built in wood, of which 50% was modular.

To complete this project, Bouygues Bâtiment Sud-Est, a subsidiary of Bouygues Construction, partnered with Ossabois, a specialist in off-site wood construction. The 100 wooden modules and 4,300 m2 of walls and floors that make up the school were manufactured in the Loire, before being assembled directly on-site at Saint-Priest. This innovative, industrialised construction process forms part of an environmentally-friendly approach, serving as a credible alternative to concrete, to reduce our greenhouse gas emissions.

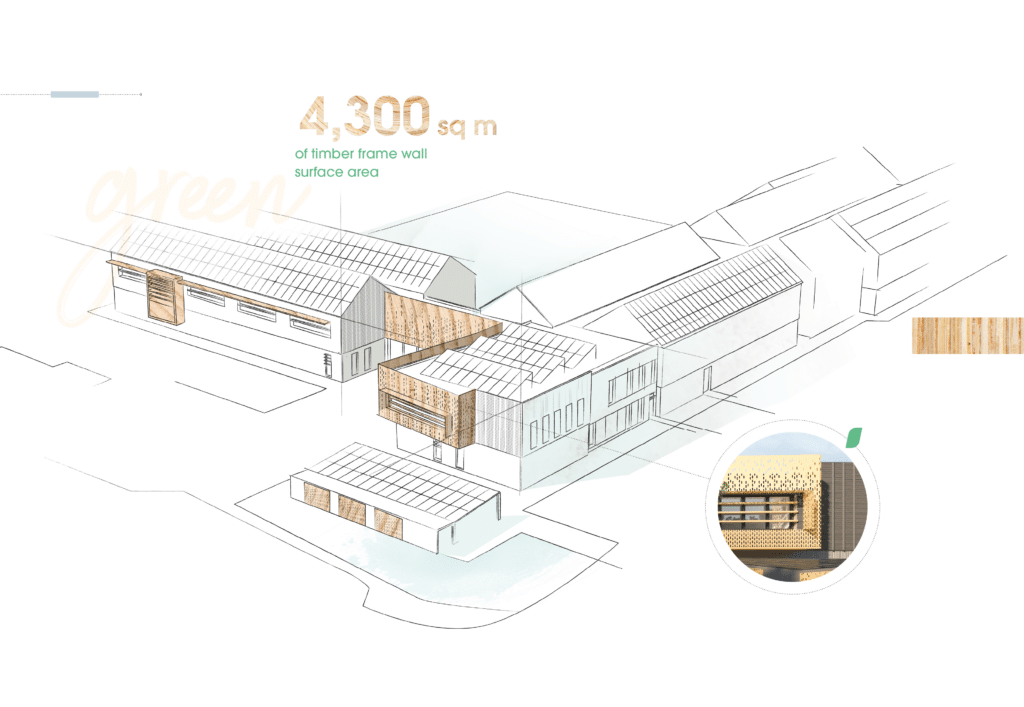

Pithiverais Secondary Schools

Two new environmentally friendly secondary schools in Pithiviers and Dadonville, north-central France.

These two new schools have been designed using bio-sourced materials, timber frame walls and cladding, wood carpentry, with straw and hemp-flax-cotton insulation. This is a first in the Centre-Val de Loire region. The buildings will be accredited the ‘BEPOS’ net-zero label as well as being certified ‘HQE Excellent’ for their commitment to high-quality environmental standards.

You might be interested in…